- +91 96877 31331

- +91 95371 31331

- moc.amrahpahdol@ofni

A pharmaceutical ampoule is a modern automatic machine which has been designed specifically to increase the rate of production in the pharmaceutical industry. This ampoule filling and sealing machine is specifically for the filling drugs into the glass ampoules. If you’re in the business of packing liquid drugs, then most definitely, you need an Ampoule Filling Machine. It provides an effective way of filling and sealing ampoules. More importantly, going for an automatic ampoule filling and sealing machine will bring increased productivity, efficiency, and accuracy in the packaging process.

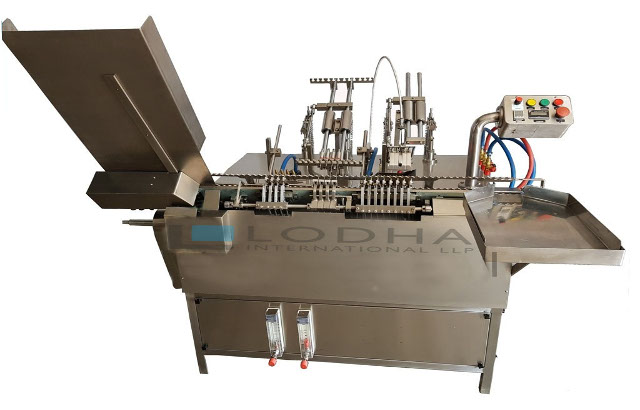

LODHA is proud to present its latest model LI – AFS models for ampoule filling. The machine is not only the best fit for pharmaceutical industry but also a preferred choice for biotech, cosmetic, veterinary & chemical industry. The Machine is built on Stainless Steel square pipes frame & totally encompassed with Stainless Steel coverings in pleasing matt finish design. The advantages to use LODHA LI-AFS machine of ampoule fillings are as follows:

LODHA LI-AFS machines are known for its smooth operations. The infeed conveyor receives the ampoules from the sterilizing tunnel. Later the ampoules are loaded into the conveyor belt into a screw conveyor in the upright position. What happens again is that the screw conveyor then transports the ampoules to the segment wheel to be carried to a conveyor cradle. It is worth noting that the conveyor cradle carries 8, 6 or 4 ampoules in a group through various stations. LODHA’s Ampoule Sealing Machine also perform pre-gassing, before filling, filling, post-gassing after filling, pre-heating, heating which is done in vertical positions.

| Sr.No. | Machine Model | LI-AFS 1 | LI-AFS 2 | LI-AFS 4 | LI-AFS 6 |

|---|---|---|---|---|---|

| 1. | No. of Head | Single | Two | Four | Six |

| 2. | Ampoule Handling Range | 1 ml to 20 ml | 1 ml to 20 ml | 1 ml to 10 ml | 1 ml to 10 ml |

| 3. | Production Output | 15 to 30 ampoules/minute |

30 to 55 ampoules/minute |

55 to 100 ampoules/minute |

80 to 150 ampoules/minute |

| 4. | Filling Accuracy | ±1% | ±1% | ±1% | ±1% |

| 5. | Require Gas for Sealing | LPG & Oxygen (O2) | LPG & Oxygen (O2) | LPG & Oxygen (O2) | LPG & Oxygen (O2) |

| 6. | Nitrogen Flushing | Pre & Post Nitrogen Flushing Available | Pre & Post Nitrogen Flushing Available | Pre & Post Nitrogen Flushing Available | Pre & Post Nitrogen Flushing Available |

| 7. | Power Specification | 0.5 H.P | 1 H.P. | 1 H.P. | 1 H.P. |

| 8. | Electrical Characteristics | 230 Volts, Single Phase, 50 Hertz, 4 Wire System | 230 Volts, Single Phase, 50 Hertz, 4 Wire System | 230 Volts, Single Phase, 50 Hertz, 4 Wire System | 230 Volts, Single Phase, 50 Hertz, 4 Wire System |

| 9. | Contact Parts | Made from Stainless Steel 316L | Made from Stainless Steel 316L | Made from Stainless Steel 316L | Made from Stainless Steel 316L |

| 10. | Non-Contact Parts | Made from Stainless Steel 304 | Made from Stainless Steel 304 | Made from Stainless Steel 304 | Made from Stainless Steel 304 |

| 11. | Overall Dimension | 915mm (L) x 610mm (W) x 965mm (H) | 915mm (L) x 760mm (W) x 965mm (H) | 1200mm (L) x 1070mm (W) x 965mm (H) | 1600mm (L) x 1400mm (W) x 1400mm (H) |

If you are looking for an efficient, effective, and economical filling machine for ampoules then you are at the right place. Choose the model as per your need. LODHA is supplying the Ampoule Filling Machines to various industries across the globe. Our less maintenance, longer life, high durability makes us the preferred choice. For zero obligation and free quote send us your enquiry now.