- +91 96877 31331

- +91 95371 31331

- moc.amrahpahdol@ofni

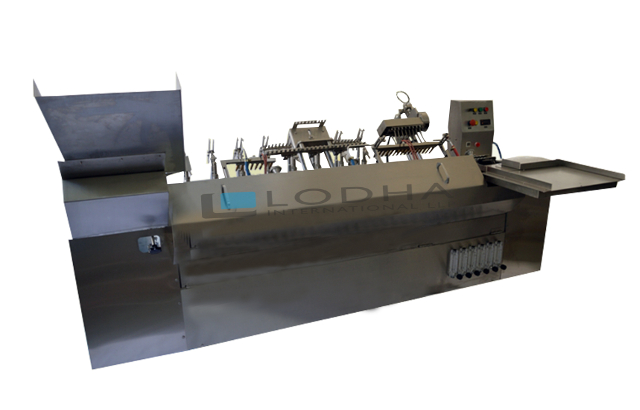

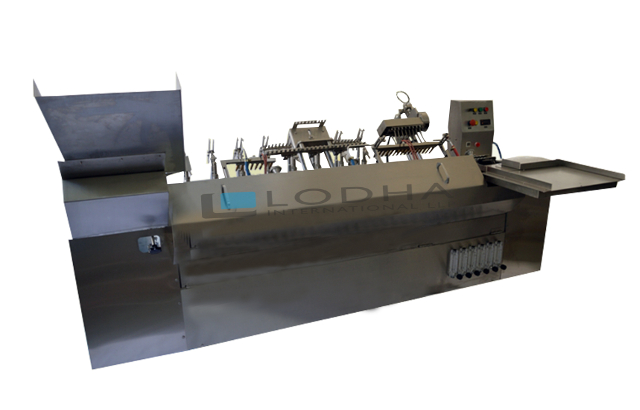

LODHA presents the all-new model LI-AFS 8 for ampoule filling. The machine works on the principle of slant travel as it progresses with filling and sealing of ampoules. The model LI-AFS 8 incorporate and adjust with the wide range available of ampoule neck’s dimension and thicknesses. The machine is versatile enough to fill and seal all standard dimension ampoules. The High Speed Ampoule Filling and Sealing Machine from LODHA is erected from a square pipe frame made of pure stainless steel alloy. The ampoule machine also encompasses with S. S. Coverings. The look of model LI-AFS 8 is pleasing enough to keep the productivity on a higher scale as it comes with a pleasing matt finish. To ease down the cleaning and maintaining the process of the machine, a large open area is given at the bottom. The model comes with a pendant type electrical control panel for ease of its operation and safety. The Salient Features are as follows:

LODHA has built this model to adjust for ampoules made from glass and plastic. The machine is a live example of technological advancement as it can also seal and fill environmentally sensitive liquids and acids that should get sealed as soon as they get to pour in ampoule to avoid any contamination.

As a futuristic Ampoule Filling Machine Manufacturer, we designed the LI-AFS 8 model to carry out the filling procedure of both liquid and powder.

The operational process is also kept simple keeping in mind the user part. The ampoules first put in the tray that is directly get loaded to slant hopper. The process then starts, wheel start to deliver one at a time moving in the rack in four’s. The rack gets stopped sequentially and during the stoppage, the pre-gassing, filling, post gassing, pre-heating, and final sealing are done of the ampoule. The sealed and finished ampoules are then collected in a tray with no human touch involved in the entire process.

| Sr.No. | Machine Model | LI-AFS 8 |

|---|---|---|

| 1. | Ampoule Filling Range | 1 ml to 10 ml |

| 2. | Production Output | 200 ampoules/ min. |

| 3. | Filling Accuracy | ± 1% |

| 4. | Require Gas for Sealing | LPG & Oxygen (O₂) |

| 5. | Nitrogen Flushing | Pre and Post Nitrogen Flushing Available |

| 6. | Power Specification | 1 H.P. |

| 7.. | Electrical Characteristics | 230 Volts, Single Phase, 50 Hertz, 4 Wire System |

| 8.. | Contact Parts | Made from Stainless Steel 316L |

| 9. | Non-Contact Parts | Made from Stainless Steel 304 |

| 10. | Overall Dimension | 1180mm (L) x 1075mm (W) x 975mm (H) |