- +91 96877 31331

- +91 95371 31331

- moc.amrahpahdol@ofni

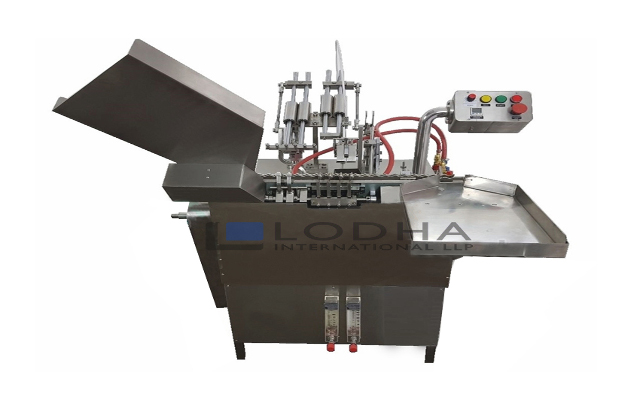

Two Head Ampoule Filling and Sealing Machine Model: LI-AFS 2 built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

The Two Head Ampoule Filling and Sealing Machine unit built on S. S. Square pipe frame and totally encompassed with S. S. Coverings, in pleasing matt finish, Further, the large opening available at the bottom side for ease of absolute cleaning. The pendant type electrical control panel is lifted from machine for ease of operation and safety.

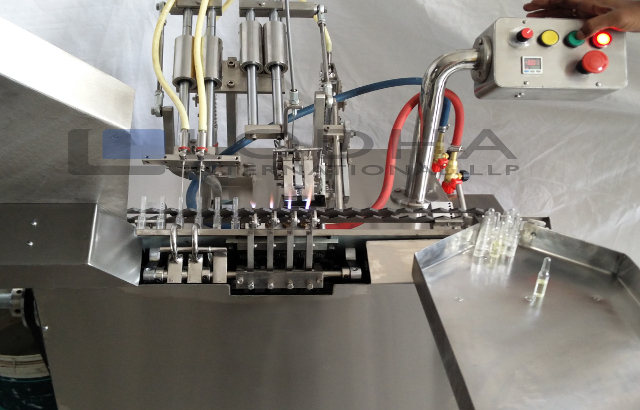

The sterilized ampoule tray directly loaded in to slant hopper of the unit. The Synchronized star wheel delivers ampoules one by one on moving eccentric ampoule rack in two’s. During the stoppage of rack sequentially pre-gassing, filling, post gassing, pre heating and final sealing is achieved. Duly filled sealed ampoules then collected on collection tray automatically without hand touch.

| Sr.No. | Machine Model | LI-AFS 2 |

|---|---|---|

| 1. | No. of Head | Two |

| 2. | Ampoule Filling Range | 1 ml to 10 ml |

| 3. | Production Output | 30 to 55 ampoules/ min. |

| 4. | Filling Accuracy | ± 1% |

| 5. | Require Gas for Sealing | LPG & Oxygen (O₂) |

| 6. | Nitrogen Flushing | Pre and Post Nitrogen Flushing Available |

| 7. | Power Specification | 1 H.P. |

| 8.. | Electrical Characteristics | 230 Volts, Single Phase, 50 Hertz, 4 Wire System |

| 9.. | Contact Parts | Made from Stainless Steel 316L |

| 10. | Non-Contact Parts | Made from Stainless Steel 304 |

| 11. | Overall Dimension | 1180mm (L) x 1075mm (W) x 975mm (H) |